How can a supplier management software reduce risk?

Introduction

Supplier management software (SMS) is one of the most important tools in any business’s toolkit. It can help you manage and track your supplier relationships, ensuring that you’re getting the best possible products at all times. But what are the benefits of using SMS? Let’s take a closer look. In this blog post, we will explore the five major benefits of using supplier management software. From reducing risk to improving communication, read on to learn more about the benefits of supplier management software.

The Role of Supplier Management Software in Risk Reduction

Supplier management software can play a pivotal role in risk reduction for businesses. By automating and organizing the process of supplier selection, management, and compliance, these programs can help reduce the potential for costly mistakes and liability.

Additionally, by mapping suppliers against relevant business standards, supplier management software can help ensure that suppliers meet applicable quality and safety requirements. This information can be used to identify potential problems early on, before they become too costly to fix or remediate.

Finally, supplier management software can help identify and address any issues that may arise between suppliers and customers. By tracking interactions between all parties involved in a supply chain—from procurement to delivery—software like this can help prevent disputes from turning into full-blown conflicts.

Types of Supplier Management Software

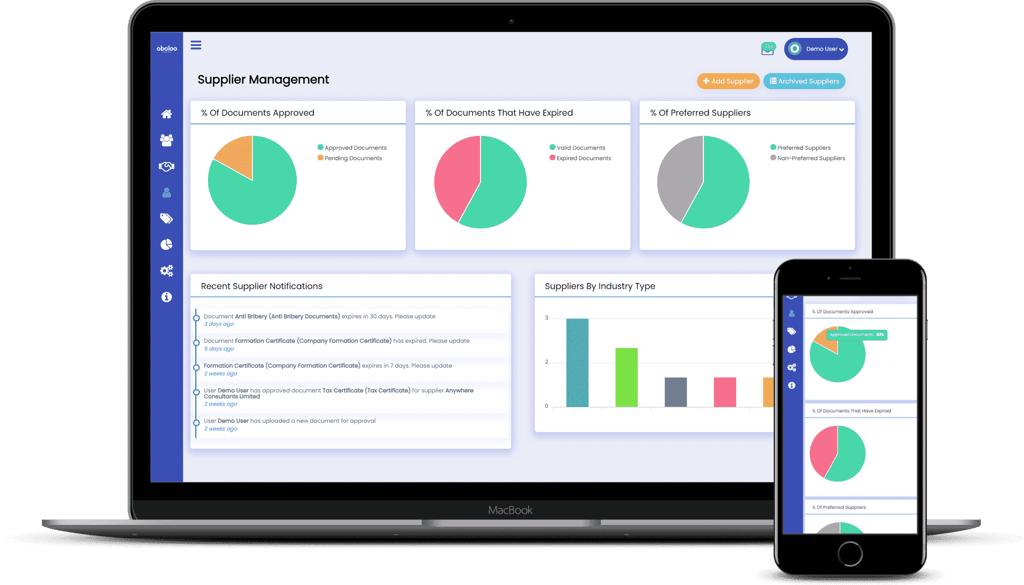

Supplier management software can help reduce risk for businesses by tracking supplier performance and compliance. This information can help identify issues early and prevent them from becoming larger problems. Additionally, the software can provide a dashboard that shows how suppliers are performing overall as well as specific areas of improvement.

Benefits of Using a Supplier Management Software

Supplier management software can help reduce the risk of supplier compliance issues. This software can help manage inventory, billings, and payments. It can also help track supplier performance and identify potential problems early. By managing the relationship with your suppliers in a more organized and efficient manner, you can reduce the risk of future problems and save money in the long run.

What is Supplier Information Management?

Supplier information management (SIM) software can help reduce risks associated with supplier relationships by providing a centralized location for managing supplier data. SIM software can also help suppliers improve communication and collaboration between themselves, which could lead to increased efficiency and better quality products.

Strategic Importance of a Third-Party Risk Management System

A third-party risk management system can significantly reduce the risks associated with supply chains and procurement. By tracking and managing risks from multiple sources, a well-executed system can help organizations mitigate potential problems before they become major issues.

Steps to Implementing a Third-Party Risk Management System

There are several steps that must be taken in order to implement a successful third-party risk management system. First, it is important to determine the specific risks that concern your organization and which parties pose the greatest risk. Next, you need to develop a comprehensive list of those entities and identify their relevant transactions and relationships. Finally, you need to develop measures to track and monitor these risks throughout the supply chain.

Some key considerations when developing a third-party risk management system include:

Determining who poses the greatest risk: A well-executed system will focus on identifying and mitigating risks posed by entities that pose the greatest threat to your business. This might include companies with questionable financial status or histories, suppliers with questionable quality control or safety records, or customers with a history of fraudulent behaviour.

Identifying relevant transactions and relationships: A strong risk management system will track all relevant transactions between party involved in order to better understand their relationships and how they impact each other. This information should be compiled into centralized databases for easy access by all members of the team responsible for managing risks.

Developing measures for monitoring risk: Once all relevant information has been collected.

What is Third-Party Supplier Risk Management?

Third-party supplier risk management (TP RM) is a process that helps organizations identify, assess, and manage the risk associated with their relationships with third-party suppliers. TP RM can help reduce the chances of encountering problems with a supplier and protect an organization’s assets.

TP RM includes the identification of risks related to the supplier, such as financial stability, quality, delivery times, and compliance with contractual obligations. It also involves assessing the likelihood of future incidents and developing contingency plans in case they occur. Finally, TP RM includes monitoring and managing relationships with suppliers to ensure compliance with established standards and guidelines.

In order to effectively perform TP RM, an organization must have a comprehensive understanding of its suppliers’ business operations and structure. Additionally, it must have effective communication channels open between its own staff and those within the supplier network. Lastly, TP RM software can play an important role in facilitating these processes by providing comprehensive reporting capabilities and easy access to relevant data.

How to Carry Out Supply Chain Monitoring?

There are a few steps that you can take to reduce supply chain risk. One way is to use a supplier management software. This software will help you track and manage your suppliers. It can also help you identify any problems early on, before they become large problems.

Another way to reduce risk is to have a good process in place. This process should include things like requirements gathering, planning, and execution. The goal is to create a system that flows smoothly and doesn’t leave any gaps or areas for error. If everything goes according to plan, you will minimize the chances of an issue happening in the first place.

How Managing Supplier Relationships can Protect Your Business

Supplier management software can help mitigate risk by tracking supplier performance, communication, and compliance. By understanding the challenges your suppliers face and their solutions, you can create a more effective relationship and protect your business.

A good supplier management system will keep track of your suppliers’ performance indicators such as delivery times, quality control rates, and invoicing accuracy. This information can be helpful in determining where improvements need to be made. Additionally, a supplier management system will allow you to communicate with your suppliers electronically, ensuring that all pertinent information is shared in a timely manner.

It is important to comply with all applicable regulations when working with suppliers. A supplier management system can help identify any potential violations and take corrective action accordingly. By monitoring supplier performance regularly and enforcing compliance policies, you can avoid any costly penalties or lawsuits down the line.

Conclusion

Supplier management software can play an important role in reducing risk for businesses. By tracking supplier performance and compliance, the software can help identify issues early and address them before they become serious problems. In addition, the software can help suppliers improve their processes and systems, which can reduce costs and improve quality.